Nano World Off The Radar For Most

24 Jan 2007

Sunscreens contain nano particles, carbon and titania nanotubes show promise and nano structures are the rage in engineering schools. While the proliferation of nano research may signal a mini revolution, outside the realms of business and science, this insurgency may be no more than a whisper, according to an international team of researchers.

"In the last 15 years we have continuously been exposed to a variety of emerging technologies - biotechnology, information science and technology, cognitive science and now nanotechnology," says Dr. Akhlesh Lakhtakia, the Charles Godfrey Binder Professor of Engineering Science and Mechanics at Penn State. "Education is the key to understanding these areas."

However, when it comes to nanotechnology, Lakhtakia and his colleagues found that people in most segments of the economy are not paying much attention. Or, if they are aware of the field, the reactions and actions are overly enthusiastic, uninformed or alarmist.

Lakhtakia, working with Debashish Munshi, associate professor, management communications and Priya Kurian, senior lecturer, political science and public policy, University of Waikato, New Zealand, and Robert V. Bartlett, the Gund Professor of Liberal Arts, University of Vermont, looked at how technologists/scientists, business and industry leaders, government agencies, social science researchers, fiction writers, political activists, science journalists and writers and the general public view nanotechnology.

Scientists have, of course, picked up on nanotechnology. The word proliferates through the literature and is prominent in proposals for funding. In an article in the international journal Futures, published by Elsevier, tresearchers note that "entrepreneurial technoscientists have learned to align their research efforts with the latest terms in vogue." However, it is not always clear what that nanotechnology means.

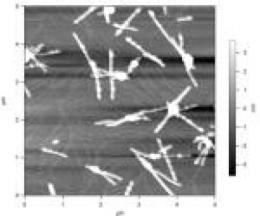

"Carbon nanotubes, quantum dots, sculptured thin films, single-electron transistors, nanofluidic sensors and biomimetic substances are all examples of evolutionary nanotechnology," says Lakhtakia. "None has yet had any significant presence in the marketplace and these developments will not be real for many years."

Currently, normal incremental changes bring sizes down to 100 nanometers - and, therefore, qualify research as nanoscience. However, simply making particles smaller for cosmetics or reinforcing plastics with carbon nanofibers is not breakthrough science, although these advances are turning out to be lucrative.

Business leaders view nanotechnology with cautious optimism. Most investment aims to improve existing products by creating smaller components or smaller products with less interest in new materials or products. Investors are wary of a nanotechnology boom turning into a dot.com-like bust.

Government and quasi-official organizations find nanotechnology important. The U.S. established an Interagency Working Group on Nanotechnology in 1996 and in 2000 the National Nanotechnology Initiative began coordinating efforts in nanotechnology. The National Science Foundation conducted a workshop on the societal impacts of nanotechnology in 2000 and concluded that, while there were technological and economic benefits to come, the societal impacts down the road were unknown. They recommended including social scientists in the NNI.

Among social scientists, little work on nanotechnology exists. While some have begun to study the area, there is little published. Reports from government agencies, scientists and business interests form the basis of the little that does exist. Some social scientists find nanotechnology interesting and beneficial, but others equate nanotech with areas they found frightening such as genetic engineering or cloning. Currently no nanotechnology law exists and legal experts believe that current law is sufficient to handle future needs with modification.

Fiction writers have covered nanotechnology, both good and bad, for a long time. Novels like Crichton's "Prey" emphasize the negatives of nanotechnology, while others expand on the possibilities. These writers reflect the hopes and fears of the scientific community and feed the nascent research of the social scientists. A Canadian activist group produced a series of reports on the social implications of nanotechnology and urges caution in using nanotechnology. Greenpeace called for a moratorium on nanotechnology due to potential nanoparticle toxicity. Many anti-nanotechnology activists predict the creation of destructive, uncontrollable life forms from nanotechnology. However, some activists realize the potential good and suggest caution as the best approach to development.

Science writers and journalists report the scientific research as it comes into the literature. They also cover the reports evaluating nanotechnology, such as the Canadian reports on social implications. Science writers have not yet produced broad evaluations of the field, but have begun to evaluate the business aspects in the cautionary context of a dot.com bust.

"The paucity of debate and critical analysis on the implications of nanotechnology in the popular media is reflected in the general lack of public awareness of the implications of nanotechnology," according to the researchers.

The researchers find the general public only vaguely aware of nanotechnology. The public sees nanotechnology as having some benefits, but is concerned with how business and industry develop the field. In the U.S., the idea of science as a neutral endeavor creates a view of nanotechnology as good, providing untold opportunities. However, the majority is unaware of exactly what nanotechnology is and of the potential problems in its development.

"Schools must find a way to interweave science, engineering, liberal arts, literature and history so that emerging fields like nanotechnology, biotechnology and cognitive science can be understood and evaluated by the general public," Lakhtakia of Penn State says. "Lifelong learning is also necessary to keep up with the changes as they come along." ###

Contact: A'ndrea Elyse Messer

Penn State

http://live.psu.edu/

http://www.medicalnewstoday.com/medical ... wsid=61394